The Project Phoenix

📘 The Goal and the Theory of Constraints:

A Timeless Guide to Operational Excellence

Introduction

In 1984, Dr. Eliyahu M. Goldratt published his seminal work, The Goal: A Process of Ongoing Improvement.

This Socratic-style novel follows Alex Rogo, a plant manager racing against time to resolve cost and due-date issues within 90 days—or face the shutdown of his plant.

Since its release, The Goal has:

- Sold over six million copies

- Been integrated into MBA curriculums worldwide

- Influenced generations of business leaders

At the heart of the book lies the Theory of Constraints (TOC)—a methodology that revolutionized how we think about productivity and process improvement.

🧠 The Five Focusing Steps of TOC

Goldratt introduces a five-step process to identify and manage constraints in any system:

1. Identify the Constraint

- Determine the resource (person, machine, material, etc.) that limits the system’s overall output.

- Misidentifying the constraint leads to ineffective solutions.

- Example: In the narrative, Brent is identified as the constraint affecting service restoration.

2. Exploit the Constraint

- Maximize the utilization of the constraint.

- Minimize downtime and ensure it focuses on the most critical tasks.

- Example: Brent’s time is protected from distractions and unplanned work.

3. Subordinate Everything Else

- Align all other processes to support the constraint.

- Adjust workflows and priorities to avoid overwhelming the constraint.

- Drum-Buffer-Rope: A scheduling mechanism to synchronize work with the constraint’s capacity.

4. Elevate the Constraint

- Increase the constraint’s capacity through:

- Additional resources

- Process improvements

- Technological upgrades

5. Repeat the Process

- Once the current constraint is resolved, identify the next one.

- Continuous improvement is key to long-term success.

🧠 Goldratt’s Insight: Improvements made anywhere besides the bottleneck are an illusion.

🔍 Understanding Constraints

Goldratt emphasized that most systems are limited by a small number of critical resources. These bottlenecks dictate the system’s output. Without a trusted system to manage the flow of work to the constraint, it becomes underutilized—wasting potential and reducing throughput.

🏗️ Design, Stability, and Business Outcomes

- Design Matters: Projects like “Phoenix” highlight how poor design leads to unplanned work and instability.

- Outcome vs. Process: Focus on what truly matters—business outcomes, not just task completion.

📚 Other Influential Management Frameworks

🔺 The Five Dysfunctions of a Team – Patrick Lencioni

- Identifies core dysfunctions like:

- Lack of trust

- Fear of conflict

- Emphasizes building trust and vulnerability for team success.

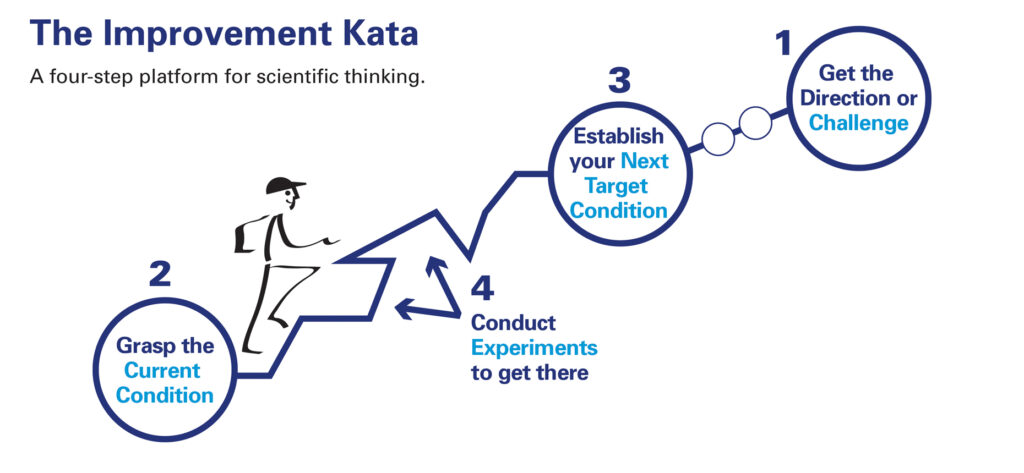

🧬 Toyota Kata – Mike Rother

- Promotes systematic routines (kata) to drive continuous improvement and adaptability.

🚀 Continuous Delivery – Jez Humble & David Farley

- Focuses on:

- Reliable software releases

- System-wide performance over siloed efforts

🛠️ Release It! – Michael T. Nygard

- Guides on designing production-ready software

- Bridges development and operations

📘 Visible Ops & ITIL

- Visible Ops: Practical steps for high IT performance

- Complements ITIL’s descriptive frameworks

🧾 Kanban Methodology – Jim Benson & David J. Anderson

- Manages Work-In-Progress (WIP)

- Improves efficiency in tech environments

⚠️ WIP: The Silent Killer

Three foundational management movements agree on one thing:

- Theory of Constraints

- Lean Production / Toyota Production System

- Total Quality Management

WIP is the silent killer.

Why WIP Control Matters

- Uncontrolled WIP leads to:

- Chronic due-date problems

- Quality issues

- Job and materials release is critical to managing WIP.

Visualizing WIP

-

Kanban boards with index cards are highly effective:

- Make WIP visible

- Improve team coordination

- Enhance flow control

🧭 Final Thoughts

The Goal and the Theory of Constraints continue to offer timeless insights into operational excellence. Whether you’re managing a factory, a software team, or a cross-functional business unit, understanding and managing constraints is essential to achieving meaningful, sustainable improvement.

KATA